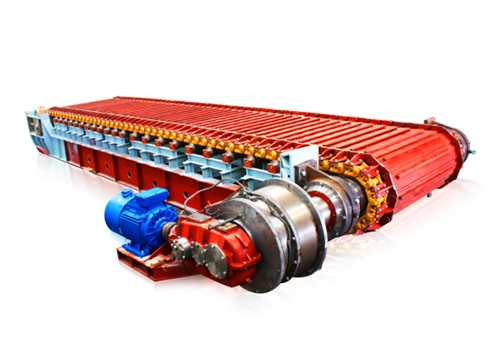

The plate feeder is to drive the power of the motor, drive the drive sprocket shaft through the reducer, and mesh with the chain pin through the sprocket teeth, drag the chain plate for continuous linear motion, and the chain plate is supported by the frame. The wheel and the sprocket are supported, and the chain is properly meshed with the sprocket by adjusting the tensioning device to complete the continuous uniform feeding.

|

Model |

Chain plate |

Production capacity t/h ┬Ā |

Electric motor |

Dimensions Length ├Ś width ├Ś height mm |

Weight t |

|||

|

Width mm |

Wheelbase mm |

Speed m/s |

Model |

Power kw |

||||

|

AF100-19 |

1000 |

19000 |

0.005-0.05 |

70 |

YP2200L1-6 |

18.5 |

21466├Ś3718├Ś4500 |

65 |

|

AF120-4.5 |

1200 |

4500 |

0.023-0.07 |

50-200 |

YP2160M2-4 |

11 |

6700├Ś4116├Ś4500 |

25 |

|

AF125-18 |

1250 |

18000 |

0.02-0.06 |

100-300 |

YP2200L-6 |

22 |

20700├Ś2725├Ś4500 |

52 |

|

AF140-3.5 |

1400 |

3500 |

0.04-0.14 |

400 |

DV200L4 |

30 |

6700├Ś4223├Ś4500 |

22 |

|

AF150-25 |

1500 |

25000 |

0.025-0.08 |

50-250 |

CB840-800-C-N |

75 |

29360├Ś3900├Ś4500 |

108 |

|

AF150-15 |

1500 |

15000 |

0.023-0.071 |

180-220 |

YP2200L2-6 |

22 |

16592├Ś4272├Ś4500 |

61 |

|

AF160-6 |

1600 |

6000 |

0.02-0.07 |

100-450 |

YP2200L1-6 |

18.5 |

9500├Ś4423├Ś4500 |

29 |

|

AF180-10 |

1800 |

10000 |

0.02-0.07 |

200-500 |

YP2280S-6 |

45 |

14500├Ś4592├Ś4500 |

59.8 |

|

AF180-20 |

1800 |

20000 |

0.02-0.06 |

150-450 |

YP2250M-6 |

2├Ś37 |

24000├Ś6671├Ś4500 |

99 |

|

AF200-10 |

2000 |

10000 |

0.01-0.07 |

150-450 |

YP2280S-6 |

45 |

14500├Ś4732├Ś4500 |

79 |

|

AF210-10 |

2100 |

10000 |

0.06-0.09 |

300-700 |

YP2280M-6 |

55 |

14500├Ś5572├Ś4500 |

87 |

|

AF220-12 |

2200 |

12000 |

0.04-0.08 |

200-600 |

YP2280M-6 |

55 |

15500├Ś6890├Ś4500 |

81 |

|

AF220-10 |

2200 |

10000 |

0.026-0.08 |

150-500 |

YP2280S-6 |

45 |

11831├Ś4840├Ś4500 |

78 |

|

AF230-10 |

2300 |

10000 |

0.05-0.09 |

200-550 |

YP2280M-6 |

55 |

11997├Ś5602├Ś4500 |

89 |

|

AF230-12 |

2300 |

12000 |

0.05-0.22 |

500-1800 |

YP2250M-4 |

2├Ś55 |

13990├Ś7100├Ś4500 |

91.3 |

|

AF240-8.5 |

2400 |

8500 |

0.12-0.25 |

300-900 |

CB560-520-C-N |

2├Ś45 |

12000├Ś5984├Ś4500 |

75.5 |

|

AF240-4 |

2400 |

4000 |

0.06 |

150-500 |

YP2200L-6 |

55 |

5594├Ś5572├Ś4500 |

43 |

|

AF300-10 |

3000 |

10000 |

0.04-0.17 |

3850 |

YP2280S-4 |

2├Ś75 |

13034├Ś8024├Ś4500 |

107 |

|

AF340-8 |

3400 |

8000 |

0.04-0.12 |

600-1750 |

YP2280M-6 |

2├Ś55 |

11940├Ś8423├Ś4500 |

105 |

Our company can provide non-standard design according to different needs of users.

Customized solutions of bulk material handling equipment are available to customers worldwide.